-

Industry

Delfzijl Powerplant

Farmsum, HollandVentilation installation.

http://klimat-solec.pl/sites/default/files/delfizjl_1.jpg

http://klimat-solec.pl/sites/default/files/delfizjl_1.jpgMälarenergi Powerplant

Västerås, SwedenVentilation installation.

http://klimat-solec.pl/sites/default/files/malanenergi_0.jpg

http://klimat-solec.pl/sites/default/files/malanenergi_0.jpgAltis Semiconductor

FranceVentilation installation.

http://klimat-solec.pl/sites/default/files/altis_semiconductor_0.jpg

http://klimat-solec.pl/sites/default/files/altis_semiconductor_0.jpgAnwil Inc.

WłocławekVentilation and air conditioning.

- CCR building,

- Transportaion station S S/s. http://klimat-solec.pl/sites/default/files/anwil_0.jpg

http://klimat-solec.pl/sites/default/files/anwil_0.jpgPolish Energy Group

BydgoszczVentilation, air conditioning, dedusting, process heat, automation and compressed air.

- Controllers’ room TG-2,

- Laboratory (ROL),

- Conveyor room,

- Coal preparing room. http://klimat-solec.pl/sites/default/files/pge_bydgoszcz_1.jpg

http://klimat-solec.pl/sites/default/files/pge_bydgoszcz_1.jpgSelected investments:

- Profeed in Trzeciewiec,

- Supravis Group in Bydgoszcz,

- Polimer in Solec Kujawski. -

Commerce

Serenada Mall

CracovVentilation, process heat, water loop installation (cooling towers) and system automation; smoke extraction in the shopping mall, ventilation and smoke extraction in the garages.

http://klimat-solec.pl/sites/default/files/serenada-krakow_4.jpg

http://klimat-solec.pl/sites/default/files/serenada-krakow_4.jpgMorena Mall

GdańskVentilation, smoke extraction and system automation.

http://klimat-solec.pl/sites/default/files/galeria_morena_3_0.jpg

http://klimat-solec.pl/sites/default/files/galeria_morena_3_0.jpgWzorcownia Mall

WłocławekMechanical ventilation, central heating, process heat, air conditioning based on a heat pump and cooling tower system with a total power of 2,650 kW, plus generators for ventilation units and system automation with monitoring.

http://klimat-solec.pl/sites/default/files/wzorcownia_0.jpg

http://klimat-solec.pl/sites/default/files/wzorcownia_0.jpgAlfa Shopping Centre

BiałystokVentilation and air conditioning based on rooftop units with heat pumps.

http://klimat-solec.pl/sites/default/files/alfa.jpg

http://klimat-solec.pl/sites/default/files/alfa.jpgSfera Mall

Bielsko-BiałaMechanical ventilation.

http://klimat-solec.pl/sites/default/files/sfera.jpg

http://klimat-solec.pl/sites/default/files/sfera.jpgH&M

Zakopane, Kielce, Zamość, Włocławek, PłockVentilation, heat pumps, automation, cool, warm and circulation water, sewerage, hydrant installation, smoke ventilation, technological water, central heating, processing heat.

http://klimat-solec.pl/sites/default/files/hm.jpg

http://klimat-solec.pl/sites/default/files/hm.jpgMazovia Mall

PłockMechanical ventilation.

http://klimat-solec.pl/sites/default/files/mazovia.jpg

http://klimat-solec.pl/sites/default/files/mazovia.jpgSelected investments:

- Fordon Mall in Bydgoszcz,

- Alfa Shopping Centre in Olsztyn,

- Alfa Shopping Centre in Grudziądz,

- Arpol Shopping Centre in Toruń. -

Transport & communication

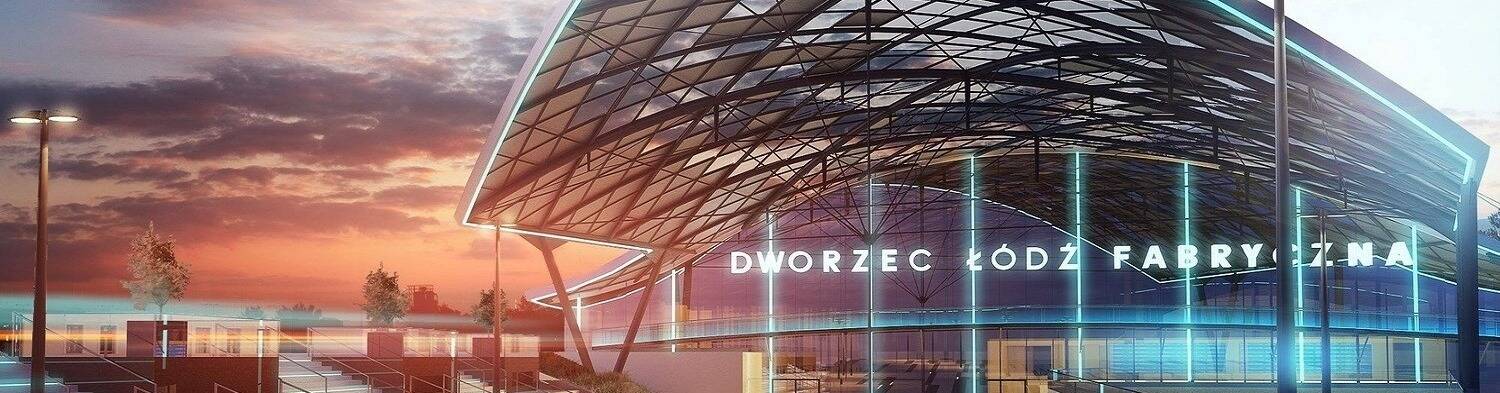

Railway Station Łódź Fabryczna

ŁódźThe company was responsible for the mechanical smoke exhaust ventilation systems and installation of household appliances. It has been used 18 453.80 m2 air ducts, 1 496 pieces of boxes, including products KLIMAT PRO.

http://klimat-solec.pl/sites/default/files/lodz_fabryczna_0_1.jpg

http://klimat-solec.pl/sites/default/files/lodz_fabryczna_0_1.jpgRailway Station

BydgoszczA construction project for the Integrated Communications Centre in Bydgoszcz. Scope of work: installation of mechanical ventilation, smoke-venting, air-conditioning and control systems, and delivery and assembly of KLIMAT PRO products:

- installation of a supply and exhaust ventilation system,

- smoke-venting system based on smoke exhaust fans with the total capacity of 250,000.00 m3,

- air-handling units in several buildings: with heat recovery, total flow-rate supply capacity of Vn 3,800.00 m3/h and exhaust capacity of Vw 3,640.00 m3/h; with cross-flow heat exchangers and rotary heat exchangers, total flow rate capacity of Vn 14,685.00 m3/h and Vw 14,735.00 m3/h, including a control system; another air-handling units with total flow rate capacity of Vn 10,791.00 m3/h and Vw 10,721.00 m3/h, and Vn 37,340.00 m3/h and Vw 38,070.00 m3/h,- air-conditioning system based on VRF air-conditioners and ceiling-mounted split air-conditioners, chilled water system with water chillers, four-pipe fan-coil units, and ceiling mounted fan-coil units capable of year-round operation, with external units located on the roof of the building.

http://klimat-solec.pl/sites/default/files/pkp2_2_1.jpg

http://klimat-solec.pl/sites/default/files/pkp2_2_1.jpgSelected investments:

- Railway Station and Shopping Mall in Myślenice,

- Railway Station in Iława. -

Health

Polyclinic Center

BydgoszczInstallation of mechanical intake-exhaust ventilation with heat recuperation.

http://klimat-solec.pl/sites/default/files/poliklinika_bydg_max_0.jpg

http://klimat-solec.pl/sites/default/files/poliklinika_bydg_max_0.jpgPolpharma

Starogard GdańskiMechanical ventilation and refrigeration units with freon installations.

- Laboratorium R&D building A,

- Hall 27B. http://klimat-solec.pl/sites/default/files/polpharma_0.jpg

http://klimat-solec.pl/sites/default/files/polpharma_0.jpgOncology Centre

BydgoszczMechanical ventilation and refrigeration units with freon installations and system automation.

- Imaging and Interventional Radiology Department,

- Nuclear Medicine Department,

- External Beam Radiation Department,

- Operating Theatre,

- Cancer Pathology Department,

- Nutrition Department,

- Spiritual Support Unit. http://klimat-solec.pl/sites/default/files/centrum_onkologii.jpg

http://klimat-solec.pl/sites/default/files/centrum_onkologii.jpgWładysław Biegański Regional Specialist Hospital

Grudziądz- Psychiatry Department,

- Pulmonology Department. http://klimat-solec.pl/sites/default/files/szpital_bieganksi.jpg

http://klimat-solec.pl/sites/default/files/szpital_bieganksi.jpgHealth and Care Centre at Mehoffera

WarszawaMechniacal ventilation.

http://klimat-solec.pl/sites/default/files/zaklad_mehoffera.jpg

http://klimat-solec.pl/sites/default/files/zaklad_mehoffera.jpgNew Hospital

Świecie- Operating Theatres,

- Intensive Care Unit,

- Endoscopy, RTG,

- Analytical Laboratory and Microbiology Rooms.

Medicam Specialist Hospital

GryficeMechanical ventilation and refrigeration units with freon installations and system automation.

- Intensive Care Unit.

http://klimat-solec.pl/sites/default/files/medicam.jpg

http://klimat-solec.pl/sites/default/files/medicam.jpgSelected investments:

- 10th Military Clinical Hospital with Clinic in Bydgoszcz,

- Pod Tężniami Nursing Home in Ciechocinek,

- Villa Park Nursing Home in Ciechocinek. -

Sport and recreation

Termy Warmińskie

Lidzbark WarmińskiRegular ventilation, installation of process heat and central heating, solar installation; fabrication and assembly of KLIMAT PRO products.

http://klimat-solec.pl/sites/default/files/termywarminskie_2.jpg

http://klimat-solec.pl/sites/default/files/termywarminskie_2.jpgAquapark Suwałki

SuwałkiMechanical ventilation based on swimming pool air handling units.

http://klimat-solec.pl/sites/default/files/aquapark_suwalki_0.jpg

http://klimat-solec.pl/sites/default/files/aquapark_suwalki_0.jpgWarszawianka Aquapark

JachrankaMechanical ventilation.

http://klimat-solec.pl/sites/default/files/aquapark_warszawianka.jpg

http://klimat-solec.pl/sites/default/files/aquapark_warszawianka.jpgFitness Academy

Wrocław, KatowiceDetailed engineering, mechanical ventilation and air conditioning. Air conditioning VRV based on FUJITSU heat cool air conditioners, automation for designed system.

http://klimat-solec.pl/sites/default/files/fitness_academy.jpg

http://klimat-solec.pl/sites/default/files/fitness_academy.jpgSelected investments:

- Education Centre of Physical Culture and Sports in Bydgoszcz,

- Orka Water Park in Bolesławiec,

- MK Bowling in Włocławek,

- Gymnasion Fitness in Włocławek,

- Kazimierz Wielki University Swimming-pool in Bydgoszcz,

- Naquarius Swimming-pool in Nakło,

- Moczydło Sport Complex (Aqua Relaks) in Warsaw,

- Wilanów Swimming-pool in Warsaw,

- Swimming-pool in Osielsko,

- Kościan Swimming-pool,

- Mońki Swimming-pool,

- PERŁA Swimming-pool in Bydgoszcz,

- Water Park in Solec Kujawski. -

HORECA

Baltic Park Molo

ŚwinoujścieMechanical ventilation and system automation for hotel rooms, cafes and an ice rink.

http://klimat-solec.pl/sites/default/files/baltic_3_1.jpg

http://klimat-solec.pl/sites/default/files/baltic_3_1.jpgGłęboczek Vine Resort & SPA

BrzozieVentilation, air conditioning.

http://klimat-solec.pl/sites/default/files/gleboczek_2.jpg

http://klimat-solec.pl/sites/default/files/gleboczek_2.jpgDiune Hotel & Resort

KołobrzegVentilation, system automation and smoke extraction for garages.

http://klimat-solec.pl/sites/default/files/diune_hotel_2_1.jpg

http://klimat-solec.pl/sites/default/files/diune_hotel_2_1.jpgCopernicus Hotel

ToruńMechanical ventilation, air conditioning based on an ice–water system, central heating, process heat, water and sewage system, system automation.

http://klimat-solec.pl/sites/default/files/copernicus_0.jpg

http://klimat-solec.pl/sites/default/files/copernicus_0.jpgHoliday Inn Hotel

BydgoszczMechanical ventilation, air conditioning based on an ice–water system, central heating, process heat, water and sewage system, system automation with monitoring.

http://klimat-solec.pl/sites/default/files/holiday_inn.jpg

http://klimat-solec.pl/sites/default/files/holiday_inn.jpgSelected investments:

- Focus Park Bydgoszcz - Pizza Hut, KFC,

- Bohema Hotel in Bydgoszcz,

- Weranda Restaurant in Bydgoszcz,

- Autos Hotel in Solec Kujawski,

- Samotnia nad Wdą Resident Hotel in Tleń,

- Auchan Shopping Centre in Bydgoszcz,

- Rzym Tavern in Pawłówek,

- MCAW Gerczak in Jażdżówki,

- Sowa Restaurant in Bydgoszcz. -

Culture

Podlasie Opera and Philharmonic

BiałystokMechanical ventilation and air conditioning.

http://klimat-solec.pl/sites/default/files/operafilharmonia_bialystok_1_0.jpg

http://klimat-solec.pl/sites/default/files/operafilharmonia_bialystok_1_0.jpgConcert hall of Music Academy

ŁódźMechanical ventilation and air conditioning and automation (BMS).

http://klimat-solec.pl/sites/default/files/sala_koncertowa_am_.jpg

http://klimat-solec.pl/sites/default/files/sala_koncertowa_am_.jpgSelected investments:

- Romantic Palace in Turzno. -

Food industry

Dr. Oetker Production plant

ŁebczDetailed engineering and mechanical ventilation.

- Freezer,

- Production plant. http://klimat-solec.pl/sites/default/files/oetker.jpg

http://klimat-solec.pl/sites/default/files/oetker.jpgSelected investments:

- Kujawy Meat Processing Plant (Drobex) in Bydgoszcz,

- National Sugar Company Inc. „Sugar Plant” in Nakło,

- Dakri Bis in Łódź,

- Olewnik Meat Processing Plant,

- Frito Lay in Tomaszów Mazowiecki. -

Paper industry

Stora Enso Poland

OstrołękaMechanical ventilation.

http://klimat-solec.pl/sites/default/files/stora_enso.jpg

http://klimat-solec.pl/sites/default/files/stora_enso.jpgCMPC Celulose Riograndense

BrazilDelivery of KLIMAT PRO products.

http://klimat-solec.pl/sites/default/files/cmpc-brazil_1_2.jpg

http://klimat-solec.pl/sites/default/files/cmpc-brazil_1_2.jpgSappi Alfeld

GermanyProduction of welded ducts made of stainless steel, aluzinc and Cor-Tenu A, dimension up to 1600 mm; assembly of multi-layer technological insulation, supporting structures for ventilation ducts, assembly of HVAC systems and production of ventilation and smoke extraction ducts and fittings.

http://klimat-solec.pl/sites/default/files/sappi_alfeld-duzy_1.jpg

http://klimat-solec.pl/sites/default/files/sappi_alfeld-duzy_1.jpgSelected investments:

- ICT Poland Kostrzyn,

- Akomex Packaging Producer in Starogard Gdański,

- Mondi Plants Pulp and Paper in Świecie,

- Intropak Celestynów,

- Agi Media Warsaw,

- Grafpol Printing House in Bydgoszcz,

- Express Media Printing House in Bydgoszcz,

- Abedik Printing House in Bydgoszcz. -

Education

Białystok University Campus

BiałystokInstitute of Biology: regular ventilation, air conditioning and ventilation technology, including individual exhaust systems for rooms exposed to contamination.

http://klimat-solec.pl/sites/default/files/kampus_2.jpg

http://klimat-solec.pl/sites/default/files/kampus_2.jpg -

Miscellaneous

Immobile K3

BydgoszczInstallation of mechanical ventilation and smoke exhaust.

http://klimat-solec.pl/sites/default/files/immobile_k3_1.jpg

http://klimat-solec.pl/sites/default/files/immobile_k3_1.jpgCity Gate

ŁódźDelivery and assembly of mechanical ventilation installation in B1 and B2 buildings.

http://klimat-solec.pl/sites/default/files/5982cfbf1687e6.51372022_0_-_rot_max.jpg

http://klimat-solec.pl/sites/default/files/5982cfbf1687e6.51372022_0_-_rot_max.jpgBusiness Incubator

BydgoszczMechanical ventilation and system automation.

http://klimat-solec.pl/sites/default/files/inkubator_przedsiebiorczosci_bydgoszcz_4_3.jpg

http://klimat-solec.pl/sites/default/files/inkubator_przedsiebiorczosci_bydgoszcz_4_3.jpgBuma Square Business Park

CracowDesign and installation of supply and exhaust ventilation system, and exhaust ventilation system - depending on the purpose of rooms. System automation, comfort air conditioning, design and installation for the changed technological solutions and equipment, taking into account the requirements laid down by the Investor.

http://klimat-solec.pl/sites/default/files/buma-square_wlasciwy_0.jpg

http://klimat-solec.pl/sites/default/files/buma-square_wlasciwy_0.jpgArena Ostróda Fair and Conference Centre

OstródaMechanical ventilation and air conditioning.

http://klimat-solec.pl/sites/default/files/arena_ostroda_1_1.jpg

http://klimat-solec.pl/sites/default/files/arena_ostroda_1_1.jpgSacral Building

ToruńVentilation, air conditioning, process heat and system automation.

http://klimat-solec.pl/sites/default/files/swiatynia_torun_1.jpg

http://klimat-solec.pl/sites/default/files/swiatynia_torun_1.jpgWiatrak Foundation

BydgoszczMechanical ventilation, central heating, process heat, an ice-water system, air conditioning (VRF) and splits, automation, heat pumps with a total power of 2*155 kW with a bottom heat source - ground probes.

http://klimat-solec.pl/sites/default/files/wiatrak.jpg

http://klimat-solec.pl/sites/default/files/wiatrak.jpgHigh Pressure Insitute

WarszawaMechanical ventilation and system automation. Mechanical ventilation and refrigeration units with freon installations with installation and system automation.

http://klimat-solec.pl/sites/default/files/iwc.jpg

http://klimat-solec.pl/sites/default/files/iwc.jpgDermika

PruszkówMechanical ventilation, air conditioning based on an ice–water system and system automation.

http://klimat-solec.pl/sites/default/files/dermika.jpg

http://klimat-solec.pl/sites/default/files/dermika.jpgSelected investments:

- Voivodeship Training Centre for Drivers in Grudziądz,

- Family Park in Bydgoszcz,

- Radio Transmitting Centre in Solec Kujawski,

- Jabil Global Services Poland in Bydgoszcz,

- Corimp Bydgoszcz,

- Ursynów City Hall in Warsaw,

- GM Records in Warsaw,

- Arpol Motor Company Showroom in Toruń,

- Opel Showroom in Bydgoszcz,

- Mercedes Showroom in Szczecin. -

Case Studies

HVAC Systems in the Jubilee House of the ’WIATRAK’ Foundation

Design solutions adopted in HVAC installations.

Design works carried out by KLIMAT SOLEC Ltd have resulted in the creation of designs of HVAC installations, installation of heat pumps with ground probes (as the lower heat source) and gas boiler room with condensation boilers. High expectations of the customer have forced the application of many advanced solutions.

Ventilation of rooms

The majority of rooms will be equipped with mechanic supply – exhaust ventilation systems. Eight such systems have been designed with total air capacity of 44,785 m3/h. The majority of them have been equipped with modular ventilating units with highly efficient modules of heat recovery in the form of rotating exchangers and energy-saving fans with direct drives of the Plug-fan type. All ventilators will be equipped with an inverter allowing the adjustment of the ventilation unit’s output to meet the current demands for ventilation air. Two large rooms: an auditorium and an art coffee-shop will be equipped with ventilation systems not only ensuring adequate ventilation but also maintaining correct temperature all year long. That is why the ventilation units servicing these rooms have been equipped with additional mixing chambers. This solution allows for rapid heating or cooling of air to the required temperature with the use of recirculated air. Moreover, in the case of the auditorium, where due to the considerable height of the room, constant air currents introduced through ceiling diffusers are necessary, a change in the quantity of fresh air will be possible depending on the current demand (controlling the quantity of fresh air with the use of air quality sensors – CO2).

The system of ventilation ducts manufactured by KLIMAT SOLEC is made out of galvanized steel sheets. KAH-I+PV and KAH+PV ventilation grills and ceiling swirl diffusers of the NSW type – manufactured by KLIMAT SOLEC, have been installed in the majority of rooms. KOK compensation hoods produced by the KLIMAT SOLEC, which provide for the supply and exhaust of air, also have been installed. In the auditorium, due to the considerable height of the room and the fact that ventilation has to ensure heating and cooling of the room, special ceiling swirl diffusers equipped with thermostatic servo-motors have been installed. They ensure adequate angle of air supply depending on the mode of operation: heating or cooling.

Due to the variable number of users, VAV air flow regulators have been installed in selected rooms. In rooms with an expected large number of users, the control of the operation of VAV regulators will be carried with the use of air quality sensors to guarantee a smooth transition (CO2). In the case of remaining rooms equipped with air flow regulators, two methods of control will be used: nominal output/minimum output (stand-by). The activation of a particular mode will be effected by the BMS system. Due to the variable operation of the individual VAV regulators, the smooth adjustment of ventilator output to current demands, as part of ventilation units’ automatics, will be enabled through a system of pressure sensors and inverters.

Air-conditioning of rooms

The air-conditioning has been based on three systems: ice water being the product of the lower heat source of the heat pumps, freon coolers working together with condensation units and VRF and Split air-conditioning systems.

The ice-water, coming from the lower heat source of the heat pumps, will feed water radiators of the ventilation units. A 33% solution of propylene glycol will be the system’s cooling agent. The temperature parameters of this agent will change depending on the current and seasonal efficiency of the heat pumps and the total cooling demand. For this reason, the radiators will be used mainly to initially cool the ventilation air. The maximum cooling power of the whole system amounts to 210 kW. In order to reduce operational costs, it has been assumed that the system will also produce cold in a passive way (i.e. when a heat pump does not produce heat, ice water is cooled naturally by the ground probes). As the cooling agent (33% solution of propylene glycol) has variable parameters depending on the current and periodical load of heat pumps, additionally, secondary freon coolers, fed by the individual condensation aggregates, will be installed in ventilation units servicing the auditorium and the art coffee-shop.

Air-conditioners which operate in VRF and Split systems have been installed as the third air-conditioning system. Two VRF systems with total cooling power of inner units of 194.7 kW have been applied. Two sets of Split air-conditioners with total cooling power of 10.5 kW have been installed in technical rooms (server room and electrical switchboard). An additional asset of the designed solutions which use VRF and Split air-conditioners is that thanks to the application of external devices such as heat pumps, it is possible to provide alternative room heating by the air-conditioners. In the case of VRF systems, the devices can operate in the heating mode with outside temperature below -20oC.

Heating systems

The majority of utility, storage and technical rooms will be heated by means of a central heating unit. The calculation parameters of this installation are: 75/55oC and total heating power of 98.5 kW. The current heating power in storage and technical rooms will be adjusted with the use of conventional thermostatic heads. In the case of utility rooms, thermal servo-motors working together with zone controllers and room temperature sensors have been installed on the radiators’ control valves. The BMS system will send details on the required temperature for a particular room to a zone controller. The solution enables an automatic control of stand-by temperature in unused rooms and the elimination of accidental simultaneous activation of heating and air-conditioning systems. It will have a direct impact on the reduction of operational costs.

Apart from the central heating unit, a technological heat installation has been designed. The calculation parameters of this installation are: 50/35oC and the heating power of 376 kW. The installation will be responsible for the feeding of water heaters in ventilation units and the air curtains protecting the main entrance to the Jubilee House. A bivalent system based on heat pumps and a cascade of condensation gas boilers will be the source of heat for the above installations and for the installation of hot utility water for the Jubilee House. The heat pumps system is composed of the lower heat source with ground probes (64 probes, each reaching the depth of 100 m), circulating pumps, buffer tanks on the side of the lower and upper heat source, as well as two heat pumps. The total heating power of the heat pumps amounts to 310 kW with the parameters of the heating water leaving the buffer tank of the upper heat source of 50/35oC. The gas boiler room will be based on a cascade of suspended gas condensation boilers with the maximum heating power of 420 kW with the parameters of the heating water leaving the in-built hydraulic coupling of 75/55oC. Such a distribution of power was a result of the limited space available for the ground probes of the heat pumps, the imposed parameters of the previously constructed central heating unit, as well as from the requirements of the hot utility water installation.

The whole system will:

- combine two installations with various requirements as far as the temperature of the heating agent is concerned,

- ensure adequate supply of individual heating circulations,

- provide for the maximum utilization of the cheapest heat source available,

- thanks to the smart management of the available heating water, ensure the reduction of consequences of possible failures,

- facilitate settlement of the heating and cooling energy delivered to the particular parts of the facility,

- substantially reduce operational costs.BMS (Building Management System)

KLIMAT SOLEC also supplies automation systems necessary for the functioning of HVAC systems in accordance with relevant design principles. Yet, the key role is played by the BMS system. This superior management system establishes the operational schedule for all HVAC devices and additionally supervises their status. The BMS system enables a further reduction of operational costs and a rapid removal of all defects.